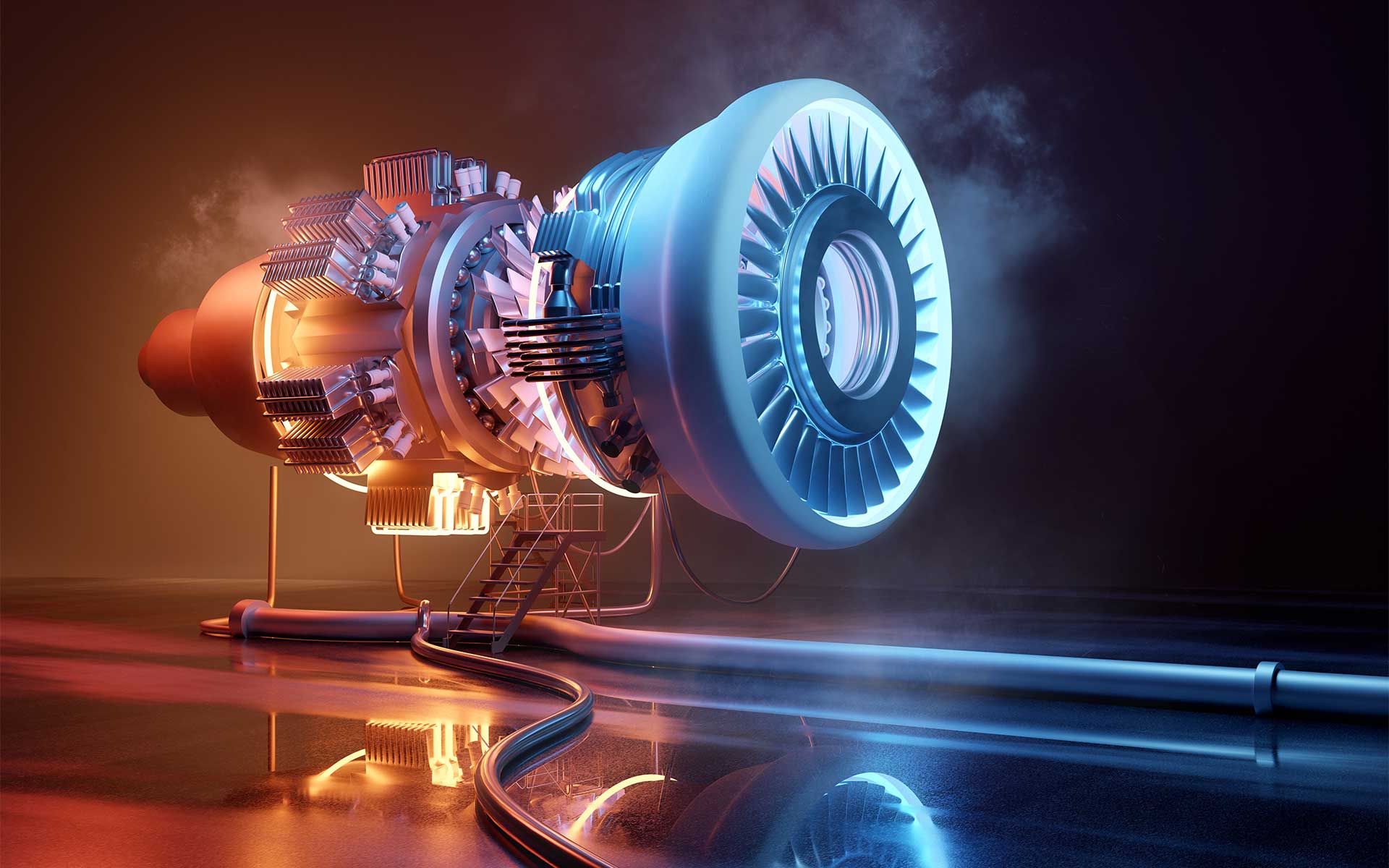

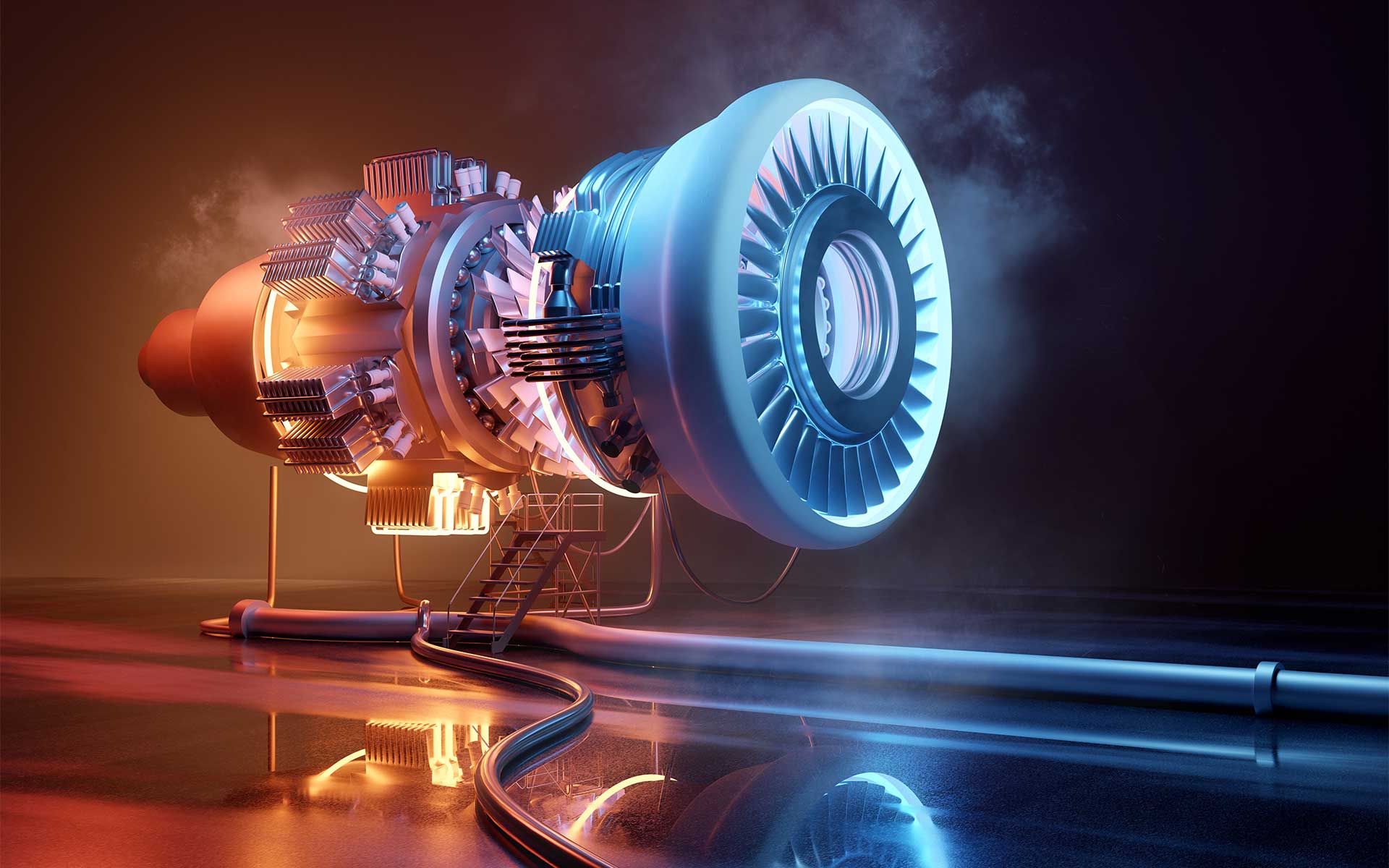

The aerospace industry encompasses a wide range of applications that involve the design, manufacturing, and operation of aircraft, spacecraft, satellites, and related systems. The applications in the aerospace industry are diverse and often push the boundaries of technology and engineering.

Electrical components play a crucial role in aerospace applications, contributing to the safety, functionality, and efficiency of various systems within aircraft, spacecraft, and other aerospace vehicles. The aerospace industry demands components that are not only highly reliable and efficient but also capable of withstanding extreme conditions and contributing to the overall success of missions, whether they involve commercial flights, military operations, or space exploration.

Today’s blog provides valuable insights into various aerospace electronic components, their critical roles, quality standards, and emerging trends to watch.

- The Role of Electrical Components in Aerospace

- Different Types of Aerospace Electrical Components

- The Importance of Quality and Standards in Electronics for Aerospace

- Future Trends in Aerospace and Electronic Components

The Role of Electrical Components in Aerospace

Electrical components designed for the aerospace industry provide the foundation for the safe, efficient, and reliable operation of aerospace applications. From aircraft to spacecraft, these critical components are integral to aerospace systems' overall design and performance by supporting essential functions like navigation, communication, power generation, and more.

Given these multifaceted and vital operational roles, successful system operation requires top-quality, reliable aerospace electronics. Therefore, the aerospace industry demands components that are highly dependable, efficient, and capable of withstanding extreme conditions. From commercial flights to military operations to space exploration, the reliable performance of aerospace electronic components is essential to operational success.

Different Types of Components for Aerospace and Electronic Systems

Aerospace electrical components encompass a wide range of specialized devices designed to meet the rigorous demands of aerospace applications, playing a crucial role in ensuring the safety, reliability, and functionality of various systems responsible for safe operation. Today’s post will focus on three of these components: circuit breakers, switches, and connectors.

Circuit Breakers

Circuit breakers play a critical role in aerospace applications by providing overcurrent protection and ensuring the safety and reliability of military & aerospace electronics, such as electrical systems onboard air and space crafts and other vehicles. In the aerospace industry, where the consequences of electrical system failures can be severe, circuit breakers are essential components that help prevent damage, fires, and other hazards during operation.

For example, in emergency situations requiring rapid power disconnection, system operators can quickly deactivate specific electrical systems by tripping the corresponding circuit breakers to help manage the problem and prevent further issues.

Switches

Switches are essential components used in various aerospace applications to control electrical circuits, systems, and functions. They play a crucial role in providing manual or automated control, enabling the crew or systems to make decisions, activate/deactivate functions, and manage various aspects of aerospace vehicles.

Some examples of systems that rely on switches for performance are cockpit and emergency controls, safety systems, and automated systems (i.e., autopilot and flight directors).

Connectors

Electrical connectors are aerospace electronic components critical to facilitating secure and reliable connections between various electrical parts, systems, and structures within aircraft, spacecraft, satellites, and other industry applications. Aerospace electrical connectors are instrumental in enabling seamless communication, efficient power distribution, and reliable functionality across a wide range of systems and components.

Here are some examples. Electrical connectors are integral to flight control systems, navigation equipment, and communication systems to help ensure precise control inputs and accurate data transmission. Aerospace electrical connectors are also crucial for interconnecting components within satellites and spacecraft, including power generation, data transmission, propulsion systems, and payload instrumentation.

The Importance of Quality and Standards in Electronics for Aerospace

Aerospace electronics manufacturers must meet rigorous quality standards to ensure each component's reliability, safety, and performance in the demanding environments of aerospace applications, which include extreme temperatures, vibrations, electromagnetic interference, and other challenging conditions. These standards encompass various aspects of design, manufacturing, testing, and quality control, as failure of an electrical component in aerospace applications can have severe consequences, ranging from equipment malfunctions to loss of life.

In the aerospace industry, established standards, such as those set by organizations like the International Organization for Standardization (ISO), provide a framework for ensuring quality, safety, and reliability. Manufacturers, suppliers, and organizations within the aerospace sector collaborate to maintain these standards and continually improve the quality of electrical components.

For example, ISO 9001 and AS9100 are quality management standards to ensure that aerospace organizations, such as electrical component stocking distributors, maintain consistent quality in their products, processes, and services. In this case, AS9100 is specifically tailored to aerospace quality requirements.

Future Trends in Aerospace and Electronic Components

Aerospace technologies and innovations have far-reaching impacts, from enabling global connectivity through satellites to advancing our understanding of the universe through space exploration. The aerospace industry is constantly evolving, driven by technological advancements, changing market demands, and the pursuit of safety and efficiency.

Several future trends are shaping the development of aerospace electrical components, including smarter, more integrated component production, advanced material application, and miniaturization for space optimization.

For example, emerging smart circuit breakers equipped with sensors and communication capabilities can provide real-time data on current loads, temperature, and fault conditions, enabling predictive maintenance and enhancing system monitoring. Also, miniaturization and space optimization are driving the development of smaller and lighter switches and connectors, which will be advantageous for aerospace vehicles where space is at a premium.

Electrical components are the backbone of aerospace applications, supporting critical functions such as safety, control, communication, power generation, and instrumentation. The aerospace industry demands efficient, highly reliable components that are capable of withstanding extreme conditions, whether they involve commercial flights, military operations, or space exploration.

As an authorized stocking distributor for military & aerospace electronics, Peerless Electronics carries top-quality products from the industry’s leading aerospace electronics manufacturers, including Safran, Honeywell, OTTO, TE Connectivity (AMP), and Sensata. Also, Peerless Electronics holds certifications in AS9100 and ISO9001:2015, ensuring that the aerospace electronic components available adhere to the rigorous quality standards required within the industry.

All aerospace electronic components ordered from Peerless Electronics also include over 50 value-added services, including custom-tailored technical support. Our experience saves time, maintains workflow, lowers costs, and allows you to allocate your workforce as needed!