When it comes to joining metal pieces, welding immediately comes to mind. However, soldering is another process that joins two or more types of metal together (pronounced “sah-dering”). In the electronics industry, understanding the soldering meaning is essential for ensuring precise and reliable electrical connections, which is crucial for numerous applications.

Today’s post covers everything you need to know about soldering, including what it is, how soldering works, what is involved, the different types of soldering, and more. As a leading electronics parts stocking distributor, Peerless Electronics offers over 50 value-added services to our customers, including soldering.

Soldering Definition: Soldering is the process of joining metal components together by melting a filler metal, called solder, and allowing it to solidify, forming a durable and conductive bond between the parts.

What is Soldered?

When something is “soldered,” it has undergone the process of soldering, which involves joining two or more metals together by heating and applying a filler metal to the joint or seam between the two metals. Soldered metals are instrumental to various applications across many industries, including electronics, plumbing, auto manufacturing, avionics, and more.

How Does Soldering Work?

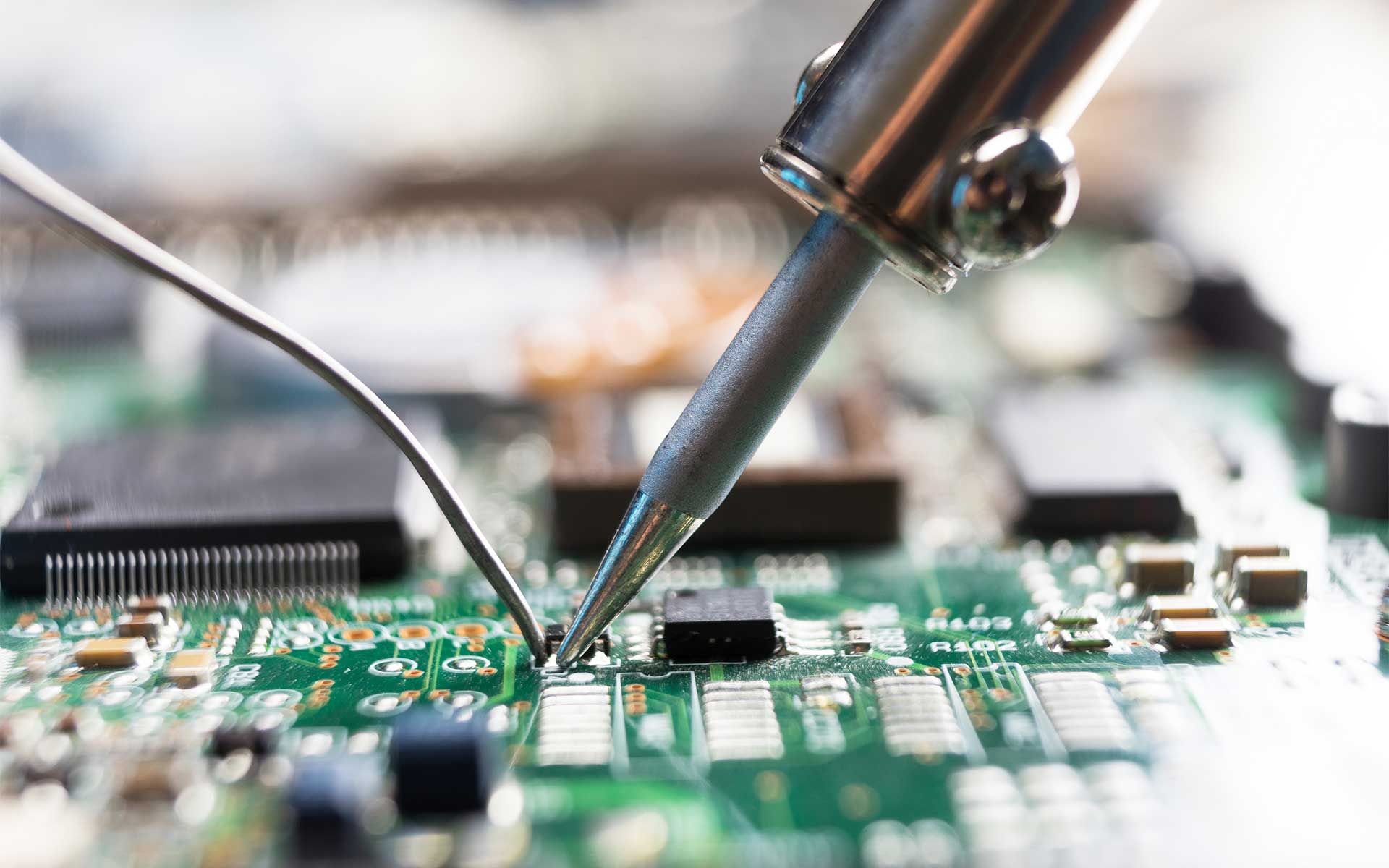

Multiple industries use soldering to join metal components reliably and efficiently. For example, soldering electronic circuit boards ensures precise and reliable electrical connections between the metal components in the electronics industry.

The soldering process involves melting solder (pronounced “sah-der”) to join two or more metal parts. Once the solder cools and solidifies, a bond forms between the metal parts. The process includes a few steps.

Preparation

Begin by thoroughly cleaning the joining metal parts to remove dirt, oxidation, or contaminants so the solder can adequately adhere to the metal surfaces. When necessary, use flux to remove oxides and impurities from the surfaces for a clean and reliable solder connection. Learn more about flux in the section below: What is Flux For Soldering.

Heating

Next, apply heat to the metal parts using a soldering iron or gun. Both tools have a heated metal tip that heats the metal surface. Be sure to clean the soldering iron tip on a wet sponge before using it.

Solder Connection or Application

After heating, apply solder to the joint between the two metal pieces. The solder will melt and fill the joint, bonding them as it cools and solidifies.

Cooling

Next, remove the soldering iron or gun and let the soldered joint cool. As the solder cools, it solidifies, permanently joining the metal parts.

Inspection

Finally, inspect the joined soldered metals for any imperfections.

What is Flux in Soldering?

After reading the above process, you might ask: what is soldering flux? Flux is a chemical compound used in soldering processes to facilitate solder flow (wetting) and prevent oxidation and corrosion during heating. Wetting is a common term used in soldering, and it describes the ability of molten solder to spread evenly across metals during joining.

Which Metals Can Be Joined With Soldering?

Soldering works well with a wide range of metals. However, success depends on using the correct solder, flux, and metal soldering technique necessary for the metal and application. Common metals connected using soldering include copper, brass, steel, titanium, aluminum, gold, silver, and nickel.

Types of Soldering

There are three techniques or types of soldering. The application’s temperature and joint strength requirements determine the best technique.

Soft Soldering

This soldering process uses solder with lower melting points, typically below 840°F/450°C. The most common soft solders are tin/lead or tin/silver/copper (when lead-free is necessary). Soft soldering has the lowest strength and melting point of the three types. Typical applications include joining electronic components, copper pipes in plumbing, or small-scale metalwork.

Hard Soldering

Hard soldering uses solder with higher melting points, ranging from 1110°F/600°C to 1470°F/800°C. Most hard solders include silver-based metals, which create stronger, more durable joints. This type of soldering is better for joining metals when higher strength and temperature resistance are required.

Brazing

Brazing is a joining process that uses brazing alloys with even higher melting points (840°F/450°C and up to 900°C/1650°F). Brazing alloys, a.k.a. brazing rods, range from copper, silver, and aluminum to tin and other metals. Brazing creates the most durable joints, which are ideal for metal repair and pipe joining applications.

Soldering Tools and Equipment

What tools do you need for soldering? Soldering equipment is essential for reliably and safely joining metals together, regardless of application.

What is a Soldering Iron?

A soldering iron is a handheld tool used to heat solder to join metals during the soldering process. It resembles a wand with a metal tip, which heats the metals and melts the solder.

Soldering iron/tips come in many shapes and sizes, making them ideal for a wide range of applications. However, they typically have a fixed temperature, so soldering iron uses often apply to simpler tasks where precise temperature control is not critical.

What is a Soldering Gun?

Soldering guns resemble a handheld drill with a trigger, heating element, and soldering tip.

Soldering guns are best for heavy-duty soldering tasks where traditional soldering irons may not provide sufficient heat or power. They use electricity and typically plug into standard electrical outlets. However, battery-operated cordless soldering guns are also available.

What is a Soldering Station?

Soldering stations are all-in-one devices that include a power supply unit, a soldering iron and holder, and temperature control settings to adjust the soldering iron's heat output. They are great for applications that require precise temperature control and more extended periods of use.

Soldering Work in Industries

Soldering is critical to industries where metal components require reliable and efficient joining. Industries that rely on soldering for reliable manufacturing, repair, assembly, and more include electronics, aerospace, automotive, medical, HVAC, metalworking, plumbing, and more.

Solder in electronics to join critical components is especially essential to assemble and repair devices like circuit boards and telecommunications equipment.

Conclusion

Soldering is a fundamental process that is widespread in industry and everyday life. Its ability to create strong, durable, and precise connections makes soldering indispensable for ensuring the functionality, safety, and longevity of countless devices and systems we rely on daily.

As a leading stocking distributor of electrical components from top manufacturers and suppliers in various industries, Peerless Electronics offers an extensive and diverse inventory of electrical parts for many industries. However, the wealth of our AS9100 / ISO9001 value-added services inclusive of soldering certified to J-STD-001 truly sets us apart from our competition.

We understand how important quality work is to performance, so our value-added soldering services are always executed by experienced technicians with the knowledge and training to perform these tasks accurately, efficiently, and precisely.

Learn more about soldering and other Peerless Electronics Value-Added Services today!

What is Soldering: FAQs

Are soldering and sautering the same thing?

No, sautering is a common misspelling for the word soldering. The confusion likely stems from soldering’s pronunciation, which sounds like sautering or saudering.

Is soldering just welding?

While both processes involve joining metals, soldering is typically used for lighter-duty applications and electronics, while welding is best for heavier-duty applications and structural components. Also, soldering requires a solder (a lower-temperature metal alloy) for joining metals versus welding, which involves forming a bond by melting the base metals together.

What is solder used for?

Solder is a fusible metal alloy used to join metal surfaces in soldering processes. It creates electrical connections between joined/soldered electronic components, wires, and printed circuit boards (PCBs). It is also used to form mechanical joints between metal components, seal and waterproof connections, assemble various components, and more.

What is a solder made of?

Solder material includes two or more metals, the most common elements being tin and lead. However, due to environmental and health concerns associated with lead, many modern solders are lead-free and may contain alternative metals such as tin, silver, copper, bismuth, or antimony. The specific composition depends on application requirements.

Is solder a conductor?

Yes, solder is a conductor of electricity, forming a conductive bond between joined metals when heated.