If you have ever questioned whether a contactor or a relay is the right choice for your latest project, then you are not alone. Confusion around these two devices is common in the electrical industry, as they look similar and have the same core functionality in modern electrical systems. However, the similarities pretty much end there.

So, while relays and contactors may appear eerily similar at first glance, there are actually significant differences that can impact their suitability for specific applications.

Today’s article breaks down those differences by examining their unique uses, highlighting key differences, and pinpointing which one will emerge as the hero for each kind of electrical undertaking. We’ll get to the bottom of this circuitry puzzle and finally find the answers to the much-asked question: contactor or relay?

Key Takeaways

- Relays control circuits with precision. They also protect systems from power surges - perfect for smaller loads up to 250VAC.

- Contactors are stronger than relays and can handle heavy-duty tasks in industrial settings, with currents starting at 9 amps and up to 1000VAC.

- Relays offer electrical isolation, which keeps us safe by separating control circuits from high-powered supply sides.

- Contactors excel in three-phase circuit applications, making them suitable for large machinery and commercial systems.

- Both devices have safety features like protective covers and overload protection but differ in size; contactors are larger due to their higher load capacity.

Uses of Electrical Relays

When managing power in our circuits, we often turn to electrical relays. These trusty devices help us precisely control the flow of electricity and serve as vital protectors, ensuring our systems run smoothly without the risk of damage from unexpected surges.

Control of Electrical Circuit Contacts

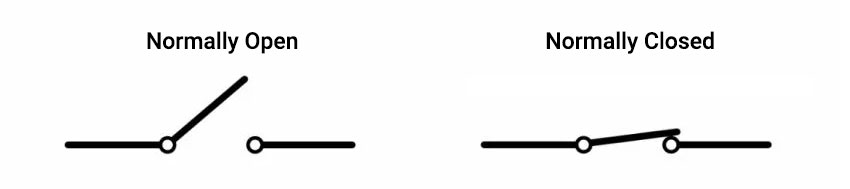

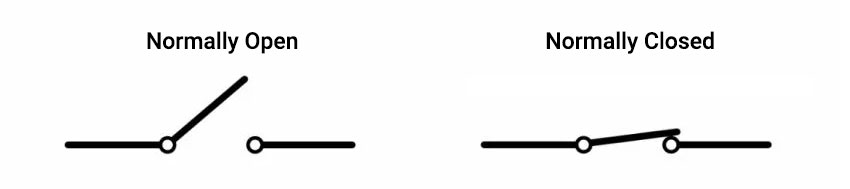

We use electrical relays to manage big power loads with just a little current, similar to turning on a high-powered motor without needing a huge switch. Relays have contacts that come in two types: normally open (NO) and normally closed (NC), which either complete or break the circuit when activated by an electromagnetic field.

With NO relays, the main circuit is open when the control circuit is not energized and closes when the control circuit is powered. Alternatively, with NC relays, the main circuit stays closed when the control circuit is not energized and opens when the control circuit is powered.

While both relays and contactors can control a main load circuit, only the electrical relay can control multiple circuits by relaying information to each.

Electrical Isolation Between Power and Control Circuits

Our gadgets need to stay safe, and that's where electrical relays come in handy. They create a protective gap between the control circuits we touch and the high-powered supply side.

This means we can manage our devices without worrying about getting hurt by the significant energy they use.

Like bodyguards for our electronics, relays stand between the sensitive controls and the heavy-duty power supply. By doing this, they make sure any problems with electricity don't mess up the delicate parts or put us at risk.

Switching Large Electrical Loads With Small Current

We use relays because they are great at handling big electrical loads, even when we only have a little bit of current to work with. Think of it like using a tiny key to unlock a huge door.

This powerful ability means that you can control things that need lots of power, such as motors and large lighting systems, without needing hefty switches or dangerous high currents where you're working.

Relays give us the power to manage these heavy-duty tasks safely and effectively. They act like gatekeepers, taking small electrical signals and using them to turn on or off much larger circuits.

This way, we keep everything under control while dealing with powerful electrical applications while keeping both the machines and ourselves safe from harm.

Additional Features for Protection Against Voltage Spikes

Some relays come with special parts like diodes or resistors. These parts help stop high voltage spikes from harming the relay.

We know protecting a relay takes more than good wiring. That's why these extra features are so important. They keep the switch safe and make sure it lasts longer. With this protection, you won't have to constantly replace your relays because of damage from unexpected voltage jumps.

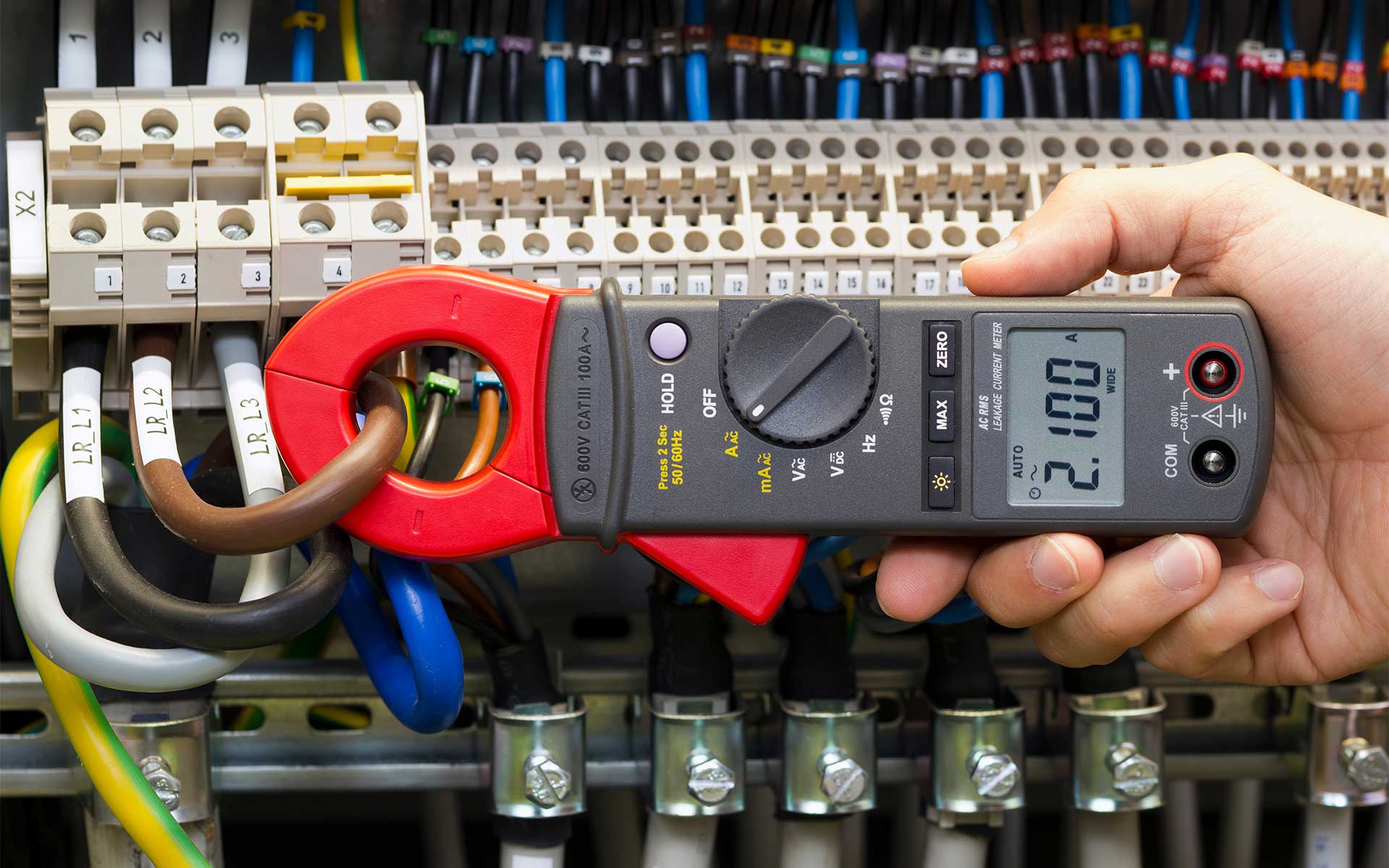

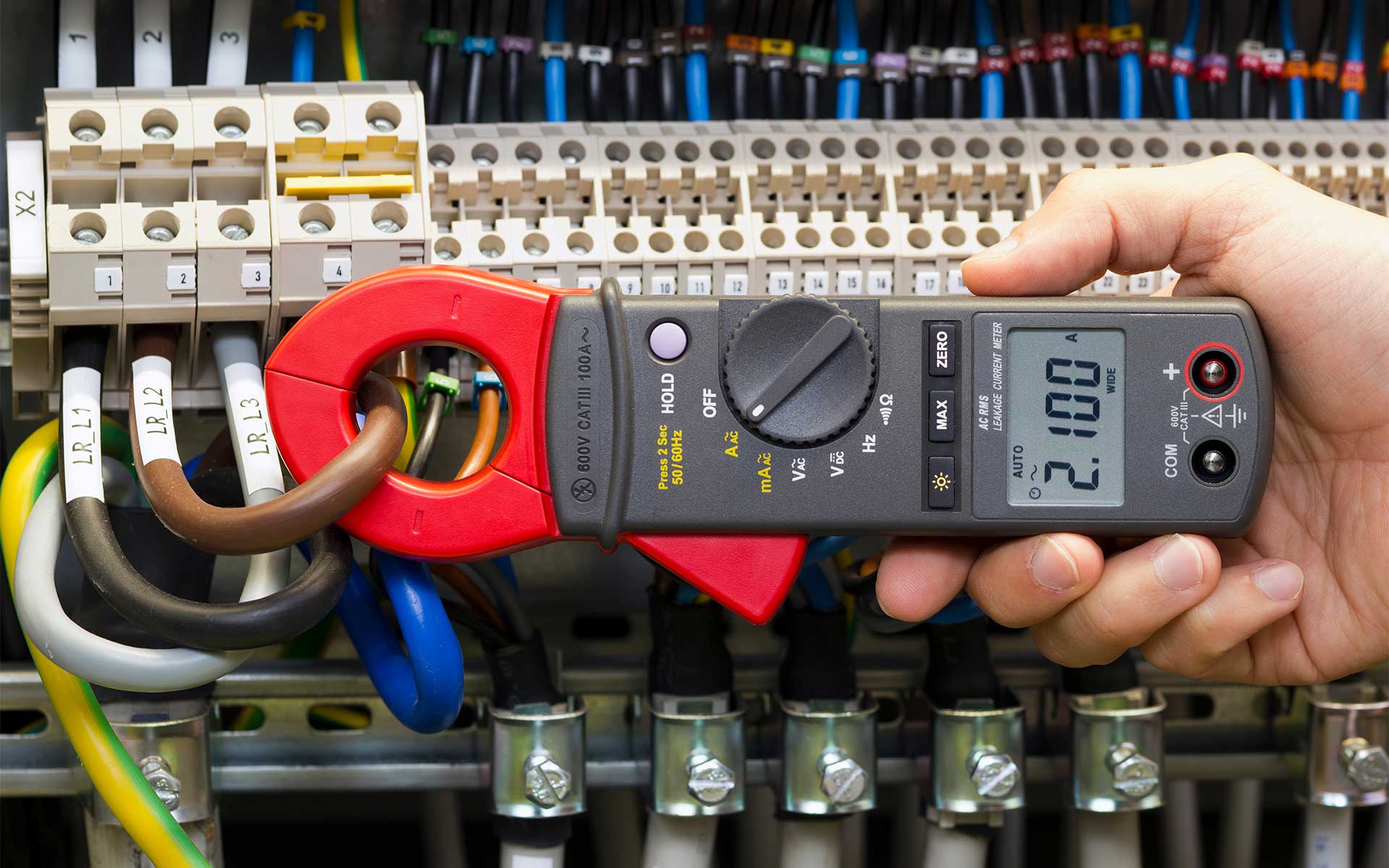

Uses of Electrical Contactors

Now, let’s talk about contactors. Electrical contactors are the muscle in power management, deftly controlling large electrical loads. So, let’s look at how their design ensures both performance and safety in demanding settings—keep reading to learn more.

Separating Control Circuits From Main Circuits

We use contactors to handle the heavy lifting in electrical systems. They keep low-power control circuits separate from high-power main circuits. This means switches or buttons that operators use don't carry the full load of electricity.

Instead, they signal the contactor to do the job.

Our safety relies on this separation, too. It prevents damage and wear on smaller components by isolating them from higher power ratings, which can be up to 1000 VAC for contactors.

Contactors are perfect for big jobs like running motors because they manage more current, starting at 9 A, and are suitable for single and three-phase power setups.

Repeated Establishment and Interruption of Electric Circuit

Electrical contactors are pros at switching things on and off again. They manage big electrical loads by connecting and cutting power fast, over and over. This 'make or break' action is what lets us control heavy-duty machines without a hitch.

Imagine turning a massive motor on and off with just a small switch – that's what they do.

In our workshops or factories, we rely on these contactors every day. They handle the tough work of starting large motors or shutting them down smoothly. These devices can take the heat of flipping circuits repeatedly without wearing out quickly.

Their sturdy build keeps them going strong - even under heavy use in industrial settings.

Control of Larger Electrical Loads in Industrial Applications

In factories full of big machines and equipment, contactors are hard at work. They help manage these heavy loads, especially when working with electric motors or large lighting systems. They can handle currents from 9 A to a massive 1000 VAC, which makes them perfect for tough jobs in industrial settings.

Their strength is vital for motor starters, which need a lot of power to get going. The contactor's robust design also safely turns high-powered heaters or capacitor banks on and off, which keeps industries running smoothly without interruption or danger.

Ensuring the Safety of Electrical Systems

Contactors help keep electrical systems safe. They handle high currents and voltages, which makes them perfect for industrial use. By safely connecting and disconnecting the power supply to loads, they prevent accidents and damage.

Contactors are critical to secure operation with motor starters, lighting control, and heating systems.

When your job includes picking the right contactor for each task, trust Peerless Electronics to provide outstanding products and support to ensure your electrical systems work well without risking anyone's safety or the equipment itself.

Safety should always top the list when choosing a contactor for any project.

Main Components and Features of Relays and Contactors

Relays and contactors are like two powerful chess pieces in the game of electrical control. Both share a family resemblance with their essential parts – coils that command action, enclosures that protect, and contacts that make or break connections. However, looks can be deceiving because, as you’ll see, contactors and relays play very different roles on the electric circuit board.

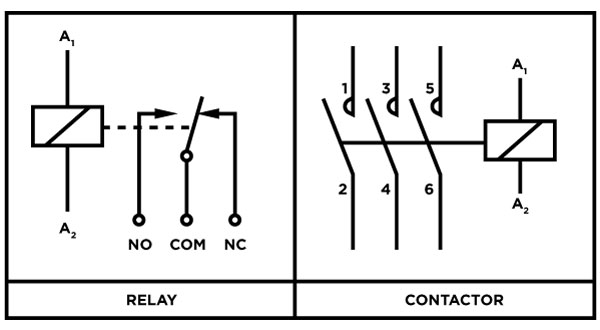

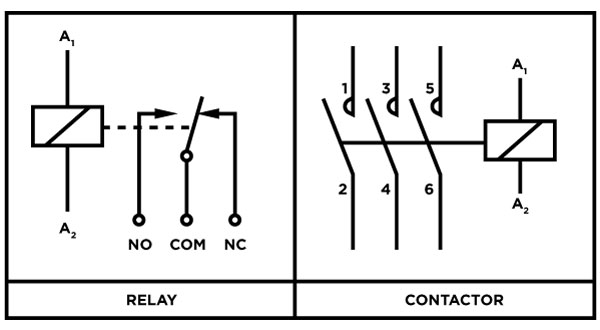

Relays: Coil, Enclosure, Contacts

We often use relays to control electrical circuits. They have a coil that creates a magnetic field when electricity flows through it. This field pulls on contact points inside an enclosure (which is a protective case).

These contacts are like switches that open or close the circuit.

Relays can handle big power loads with just a little bit of current from the control side. That's thanks to their design, which keeps the high-power and low-power parts safe from each other.

Some relays even come with special parts like diodes or resistors to protect against sudden voltage jumps. This makes them really useful for all kinds of electrical projects where safety and control matter greatly.

Contactors: Coil, Enclosure, Contacts

Contactors help us control large electrical loads, like motors in industrial settings. They have a coil that creates a magnetic field when electricity is applied to it. This action pulls the contacts together and powers up the system.

Different types of contactors include ALEV100-CA and ALEV200-CA.

Their enclosures keep everything safe inside and protect us from dangerous electric arcs because the contacts make or break the connection to start or stop the flow of electricity.

Contactors can also handle hefty currents, ranging from 9 A on up to 1000 VAC for single or three-phase circuits.

Differences Between Relays and Contactors

When navigating the maze of electrical components, we often come across these two crucial players, i.e., relays and contactors. While they look somewhat similar, a closer look reveals key distinctions that set them apart for specific tasks.

So, let’s explore how these differences dictate their roles in the world of electricity.

Load Capacity

We often choose contactors when we need to manage heavy-duty machines. They're strong enough to handle big jobs, up to 1000 VAC, making them great for industries where machinery needs lots of juice to operate.

Think about massive motors or entire factory lines – that's where contactors shine.

Relays are the go-to for less intense tasks. They work well with gadgets using 250 VAC or less, like home electronics or office devices. When the power demand is smaller and under 10 A, relays keep things safe and efficient without a fuss.

Symbols

The contactor and relay have distinctive symbols.

Symbols make our lives easier when working with electrical diagrams. They give us a clear picture of what goes where - like a map for electricians and engineers. Although the symbols for contactors and relays are unique, each follows the same universal rules so everyone can understand them the same way.

We need to know these signs to install and fix electrical systems correctly. Every symbol tells us something important about how the electricity moves through a circuit while also indicating if it’s safe or not.

They’re like a language that helps us speak about power without getting mixed up.

Suitability for AC vs. DC Loads

Contactors are perfectly suited for alternating current (AC). They handle AC loads up to a whopping 1000 volts. That's perfect for big, hungry industrial machines. Plus, they're great for both single-phase and three-phase power systems.

On the flip side, relays prefer a lighter meal. Their sweet spot is AC loads under 250 volts.

Now, when it comes to direct current (DC), they play differently. Relays can control DC power very well because they're designed for lower voltage tasks - regardless of whether AC or DC. Contactors still work with DC, but be careful because they need specific designs made just for that purpose.

If you've got a heavy-duty job with lots of power flowing through in an industrial setup, grab a contactor - they’ve got your back on those tough jobs!

Open/Closed Contact Standards

We need to know about open and closed contact standards because they show us how relays and contactors work with different circuits. Open contacts mean the circuit is off until the contacts close, which starts the flow of electricity.

Closed contacts are just the opposite; they keep the current flowing until something opens them up and stops it.

Relays often have both types of contacts, so you can pick what's right for your job. But contactors mostly come with open contacts, which works great for things like turning on big machines safely.

With standardized symbols for these open and closed states, you can easily figure out what part does what in electrical diagrams.

These standards ensure that everything runs smoothly and safely when controlling power with relays or contactors. Auxiliary contacts also play into this by adding more options to control various parts of an electrical system securely.

Ability to Control Multiple Circuits

Controlling multiple circuits can be a tough job, which is why we use contactors. They handle several circuits at once, making them great for jobs that need lots of power. Think about big machines in factories; they have loads of parts working together.

Contactors manage all that action smoothly.

Relays can also control more than one circuit with just one supply source, which is the case in homes and workplaces daily. Both devices make sure everything runs without a hitch, whether it's your garage door or an entire assembly line!

Presence of Auxiliary Contacts

We often use contactors in complex systems because they have auxiliary contacts. These extra contacts let us control several circuits without overloading the main contacts. This feature makes contactors versatile for various applications.

They can manage lighting, heating, and motor control tasks smoothly.

Auxiliary contacts play a big role in safety, too. They keep an eye on the state of the main circuit. If something goes wrong, these small helpers trigger alarms or shut down parts of the system to prevent damage or danger.

With auxiliary contacts, we have more control and better protection in our electrical setups.

Physical Size

Contactors are the big players in our electrical control systems, much larger than their relay counterparts. They need to be bigger because they handle high-power circuits and keep up with the hefty demands of industrial applications.

On the flip side, relays are smaller and perfect for less intense jobs. They fit snugly into single-phase setups where controlling low-voltage power is the name of the game.

Our toolbox isn't complete without both contactors and relays, each sized just right for their specific roles. Think of them as team members with different positions; one's size gives it strength for the heavy lifting, while the other's compact build lets it maneuver through tighter spots with ease.

Their physical dimensions reflect their purpose. Contactors stand tall when facing down high-voltage tasks, whereas relays comfortably manage smaller jobs that don't need as much muscle.

Safety Features

We take safety seriously, and that's why our contactors come with sturdy safety covers. These shields keep us safe from accidental touches of live parts. Relays also have safety measures, many featuring clear covers so you can see what's happening while staying protected.

Our devices are designed to cut power fast, keeping circuits safe during maintenance. Built-in overload protection is key to prevent damage if things get too hot or if there's a short circuit.

Safety interlocks add an extra layer of security. They make sure the system only works when it’s completely safe, like when all panel doors are closed tight. These features help us make sure everyone stays out of harm’s way while using electrical power responsibly.

Compatibility With Three-Phase Circuits

Contactors are designed to handle one or three-phase circuits, making them a go-to choice for powering up heavy machinery and large commercial setups that require more than just single-phase power.

They smoothly manage the high power demands of these systems, ensuring everything runs without a hitch.

Relays, on the other hand, stick to simpler tasks within single-phase applications. They lack the muscle for the complex job of controlling three-phase circuits found in industrial environments.

Contactors are built for these bigger challenges, so they align perfectly with the needs of equipment that rely on alternating current across multiple phases.

Conclusion

We've explored the essential uses and differences between relays and contactors. Remember, if you're dealing with smaller loads, a relay is your go-to device. For larger, industrial-sized jobs, contactors are what you need for safety and control.

Now that we’ve cleared the air between these two devices, selecting the right one for your electrical application should be a lot easier. Just remember to ensure everything fits perfectly by double-checking load capacities and voltage ratings before choosing.

After all, making informed choices keeps our circuits safe and efficient!

And remember - no matter which component is needed, you can find a wide variety of both contactors and relays in stock at Peerless Electronics. Not only are we the largest stocking distributor for leading manufacturers of these devices, but we back every product with custom-tailored technical support and value-added services.

FAQs

1. What's the difference between contactors and relays?

Contactors and relays both switch electric circuits, but contactors handle high power for things like motors, while relays are for low-power signals or devices.

2. When should I use a relay in my electrical project?

Use a relay for smaller tasks where controlling low voltage and ampere-rated devices is needed, like signal transformers or LED lighting.

3. Can a contactor control heavy machines?

Yes, contactors are made to manage big jobs by switching on large equipment that needs lots of electricity, such as those with a high horsepower rating.

4. Do relays work with both AC and DC power?

Relays do work with alternating current (AC) as well as direct current (DC), making them versatile for different kinds of electrical jobs.

5. How can I protect my circuit from too much power during start-up?

You can use inrush current limiters such as NTC thermistors to reduce big surges of electricity when you first turn on your device.

6. Why is it important to have arc suppression in an electromagnetic switch?

Arc suppression helps prevent sparks when contacts open or close inside switches like contactors and relays; this makes them safer and last longer.