The modern world runs on electricity. However, electricity needs distribution management to power all the demands we place on it effectively. That’s where electrical transformers come in. An electrical transformer helps electricity travel safely and efficiently from its source to where it's needed.

Although there are many types of electrical transformers, they all play the same critical role: matching the voltage level of electricity to the requirements of different devices and machines. Today, we’re discussing the different types of transformers and their classifications. We’ll also highlight a few leading transformer manufacturers carried by Peerless Electronics.

Different Types of Transformers

Although some distinct differences apply to each type of transformer, standard characteristics remain constant, no matter the type. For example, transformers do not have any moving parts and maintain the same input and output frequency; only the voltage levels change. Also, all types of transformers operate based on the law of electromagnetic induction, where power transfers through the magnetic flux. Finally, transformers only work with alternating current (AC) and cannot operate with direct current (DC) because a steady current does not induce a varying magnetic field needed for induction.

So, how many types of transformers are there? Quite a few! Electric transformers fall into various categories or classifications depending on different factors. Understanding the different transformer types is paramount to knowing which transformer will work best for your specific applications.

Understanding Types of Transformer Classifications

Understanding the following classifications of transformers can help determine which type is appropriate for specific electrical applications. In this next section, we will detail several categories for many of the main types of transformers. This section will not cover every type of transformer available; however, these are the most prominent in modern electronics for both industrial and consumer applications.

Types of Transformers According to Voltage Level

Categorizing transformers by voltage level is essential to ensure they meet the specific needs of different stages in the electrical supply chain, from the high-voltage transmission to low-voltage end-use. These types of transformers help facilitate efficient power transmission, distribution, and utilization by adjusting voltage levels to match specific requirements.

Step Up Transformer

This type of transformer converts voltage levels from low input voltage to high output thanks to more windings in the secondary coil. They are commonly used in power distribution grids to raise the voltage level before distribution.

Step Down Transformer

This type of transformer does the opposite, i.e., it converts voltage levels from high input voltage to low output. Step-down transformers are integral to power adapters and the circuits of mobile phone chargers.

Types of Transformers According to Core Material

Transformers help move energy by directing magnetic flow through a core, and the type of core material affects how much magnetic flow is created. Therefore, transformers with different core materials are more efficient for specific electrical applications.

Air Core Transformers

This type of transformer establishes the magnetic field in air (or any other non-magnetic medium). Without a solid core like other transformers, this type is lighter and better suited for compact and portable electronic devices.

Ferrite Core Transformers

This type of transformer has a ferrite core that enhances its magnetic properties. Ferrite core transformers are highly suitable for high-frequency applications and come in various shapes and sizes, allowing customization to meet specific requirements.

Iron Core Transformers

This type of transformer has a core composed of multiple soft iron plates. Iron core transformers can handle high power levels with relatively low losses, making them ideal for power distribution systems. They are also commonly found in household appliances and electronic devices where voltage needs to be adjusted.

Toroidal Core Transformers

This type of transformer has a toroidal (ring-shaped) core made of ferromagnetic material, like iron or ferrite. This compact, symmetrical design offers low electromagnetic interference (EMI) and stray magnetic fields. These compact and lightweight transformers provide higher efficiency, lower losses, and reduced vibrations or audible noise, making them ideal for audio equipment and medical devices.

Types of Transformers According to Purpose/Usage

Some industries require transformers with unique features or specifications to meet specific technical or operational requirements. Therefore, these types are specialized transformers designed and tailored to meet the unique needs of each application.

Power Transformer

This type of transformer is critical to electrical power systems, linking power generators to primary distribution grids. Power transformers transmit and distribute electrical energy at high voltage levels, converting low-voltage, high-current electricity into high-voltage, low-current electricity. They are typically large in size.

Distribution Transformer

Distribution or conversion transformers step down high-voltage transmission lines to lower-voltage levels suitable for use by residential, commercial, and industrial consumers. Distribution transformers are critical to enabling access to electricity for lighting, heating, communication, and other essential services.

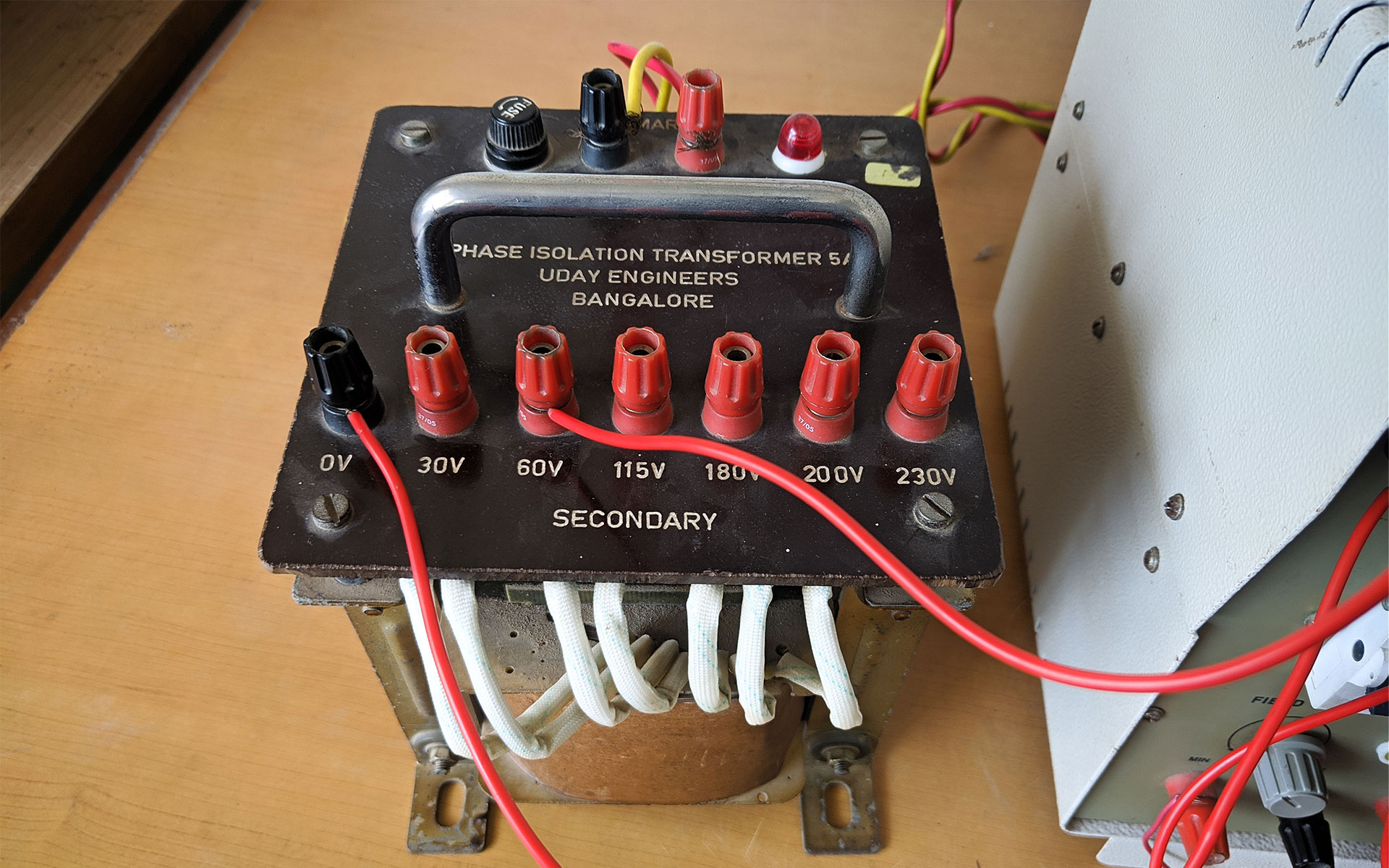

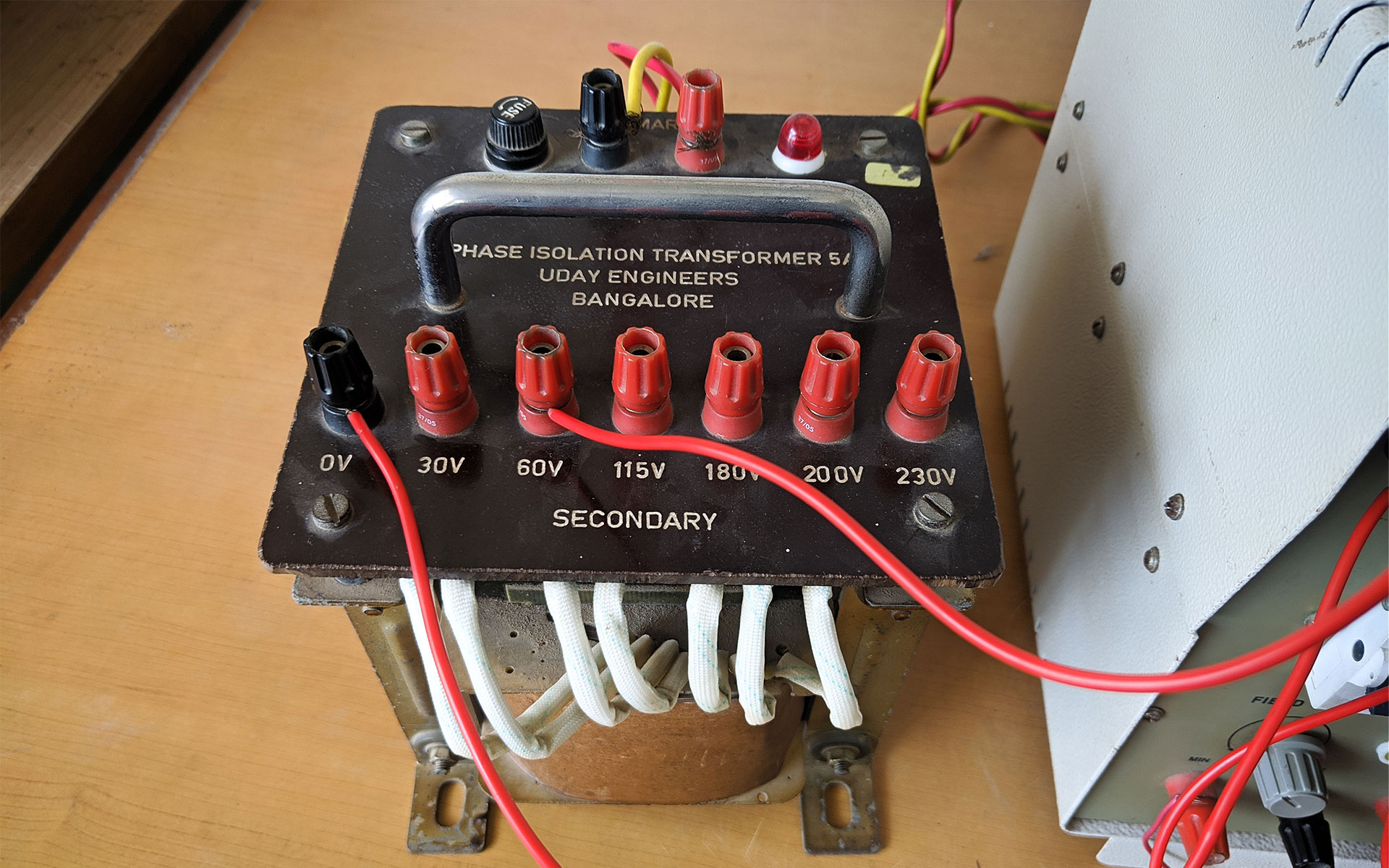

Isolation Transformer

This type of transformer provides electrical isolation between the input and output circuits while maintaining the same frequency of AC power. This isolation protects equipment from electrical noise and interference, providing reliable and stable power for critical applications. Isolation transformers protect sensitive electronic equipment and systems used in healthcare, telecommunications, laboratories, and industrial automation.

Instrument Transformers

This type of transformer can accurately measure high voltages and currents. It converts them into manageable levels for instrumentation and protective relaying equipment. Instrument transformers electrically isolate measuring and control circuits from high-voltage power circuits, ensuring the safety of personnel and equipment and preventing damage to sensitive instrumentation. There are two types: current and potential.

- Current Transformer: this type of transformer steps down high currents to levels suitable for measurement by ammeters, wattmeters, and protective relays. Applications include monitoring current flow, detecting faults, and providing feedback for control and protection systems.

- Potential Transformer: this type of transformer steps down high voltages to safer levels for measurement by voltmeters and other instrumentation equipment. It is commonly used for power systems' metering, control, and protection applications.

Types of Transformers According to Insulation

A transformer’s insulation directly impacts safety, reliability, performance, environmental compatibility, regulatory compliance, and application suitability.

Dry Type Transformer

This type of transformer uses solid insulation materials like epoxy or polyester resin to insulate and protect the core and windings/coils. Since they do not have a liquid insulator, dry type transformers are ideal for indoor installations where fire safety and environmental concerns are paramount, such as in commercial buildings, industrial facilities, and sensitive environments such as data centers and hospitals.

Oil Immersed Transformer

These types of transformers use mineral oil or synthetic fluids as the coolant and insulation medium, which allows the transformers to handle higher power loads and operate more efficiently. These transformers are standard in outdoor and high-power applications such as power substations, utility grids, and heavy industrial settings.

Encapsulated Transformer

These types of transformers utilize unique insulating techniques, including full encapsulation, to meet international safety requirements. They are ideal for low-power applications requiring minimum height and reduced magnetic radiations.

Types of Transformers According to Windings

A transformer's winding or coil arrangement is integral to its performance characteristics. The arrangement, size, and number of windings determine the transformer's voltage transformation ratio, current capacity, efficiency, safety, and suitability for specific applications.

Two Winding Transformer

This type of transformer is also known as a conventional transformer. It has two separate windings, the primary and secondary, and can step up or down voltage levels. Two winding transformers are pretty standard in industrial, residential, and commercial applications for efficient and stable power distribution and voltage regulation.

Autotransformer

Unlike traditional transformers with electrically isolated primary and secondary windings, an autotransformer has a single winding that is tapped at different points to create the primary and secondary circuits. Therefore, this type of electrical transformer can step up or down voltage levels by varying the connection point along the winding, allowing for precise control of output voltage levels within a narrow range. The autotransformer’s unique construction and function make them versatile tools for various industries, like power distribution, motor control, and lighting applications.

Types of Transformers According to Phases

The phase operation of a transformer influences voltage levels, power distribution efficiency, equipment compatibility, and overall system reliability. Transformers must be compatible with the phase configuration of the power system. Hence, single-phase transformers are suitable for single-phase power systems, while three-phase transformers are necessary for three-phase power systems.

Single Phase Transformer

This type of transformer has a primary and secondary winding and operates with a single phase alternating current. Single phase transformers help power smaller commercial and residential electrical applications like lighting and appliances.

Three Phase Transformer

This type of transformer has three sets of primary and secondary windings designed to handle three-phase AC power commonly used in industrial and commercial applications. Therefore, three phase transformers are more efficient and cost-effective for large-scale power distribution applications, like power generation plants, substations, and industrial facilities.

PowerVolt Transformers

When it comes to high-performance electrical transformers, Powervolt Group has a solid reputation for efficiency, reliability, safety, adaptability, and technological innovation. PowerVolt is a leading manufacturer of standard/off-the-shelf power transformers, PCB mounting and chassis mounting, custom transformers, isolation, control, and other industrial transformers up to 40KVA and Class 2 transformers up to 100VA. Since its founding in 1973, Powervolt has steadily grown its market share through strategic acquisitions, including the Wabash and Ensign product families.

Wabash Transformers

Wabash, part of the PowerVolt Group, offers a full range of Custom and Standard power transformers. Wabash Transformer applications include HVAC, medical, pool and spa, metering equipment, household appliances, and more. With a mission to be the highest quality and most cost-effective supplier to customers worldwide, Wabash offers ideal solutions for electrical applications through a vast selection of pre-engineered or custom-designed transformers that meet domestic and international safety agency standards.

Ensign Transformers

Since 1939, Ensign, part of the PowerVolt Group, has forged a reputation as a world-class manufacturer of electrical high frequency, customer power, and current sensing transformers, excelling in designing and manufacturing products with quality achieved by standards and certified processes to meet demand over a vast range of industrial applications. Ensign’s extensive experience ranges from powering control systems on U.S. naval destroyers to recharging handheld flashlights. Whether custom-designed or pre-engineered, customers can count on Ensign to provide quality electrical transformer products to precise specifications at the most economical cost possible.

Peerless Electronics Transformer Solutions

Transformers are essential to powering our world by enabling the efficient transfer of electrical energy between different circuits. Understanding the various types of transformers and their specific uses is critical to selecting the correct type of transformer for your application.

As an authorized stocking distributor of the Powervolt Group, including Ensign and Wabash transformers, Peerless Electronics offers all types of transformers, from pre-engineered to custom-designed. Every Peerless Electronics transformer purchase is backed by over 50 value-added services, including thorough and complete installation and maintenance support, ensuring every type of transformer perfectly aligns with your technical specifications and operational goals.

Types of Transformers FAQs

What type of transformer is the least efficient?

Typically, the least efficient type of transformer is the autotransformer. While this type of transformer can be very efficient in specific use cases, the autotransformer’s lack of isolation, susceptibility to harmonics and electrical noise issues, and more can make them less effective in broader applications.

Are there different types of current transformers?

Yes, there are several different types of current transformers (CTs). Each is designed for specific applications and operating conditions, and the main types include wound current transformers, bar-type current transformers, window-type current transformers, split-core current transformers, and more. Contact Peerless Electronics with questions about current transformers.