In any busy factory, machines need to know when to stop or start. Honeywell steps in with limit switches built tough for these very tasks. This post will delve into how these switches keep the gears of industry turning smoothly and safely.

Keep reading; it's time to switch on knowledge!

Key Takeaways

- Honeywell limit switches are built to last in tough environments like factories with lots of dust and noise. They keep machines running safely by sensing objects.

- These switches use solid - state technology for a longer life and better performance, even when they get wet or dirty.

- Switches come in different types, including ones with pre - cabled options, so setting them up is faster and easier.

Honeywell: A Leading Supplier of Limit Switches for Industrial Applications

Honeywell sets the bar high in providing robust limit switches that serve as crucial components for industrial settings, handling tough conditions with ease. These switches operate with precision to detect object presence or absence, ensuring machinery across various sectors maintain top performance regardless of environmental challenges.

Limit switches are used to sense the presence or absence of an object in extreme environments

Limit switches shine in tough spots where you need to know if something is there or not. Workers count on them to check for objects even when things get really hot, cold, or dirty.

These durable devices don't mind getting wet or dusty. They keep doing their job no matter what.

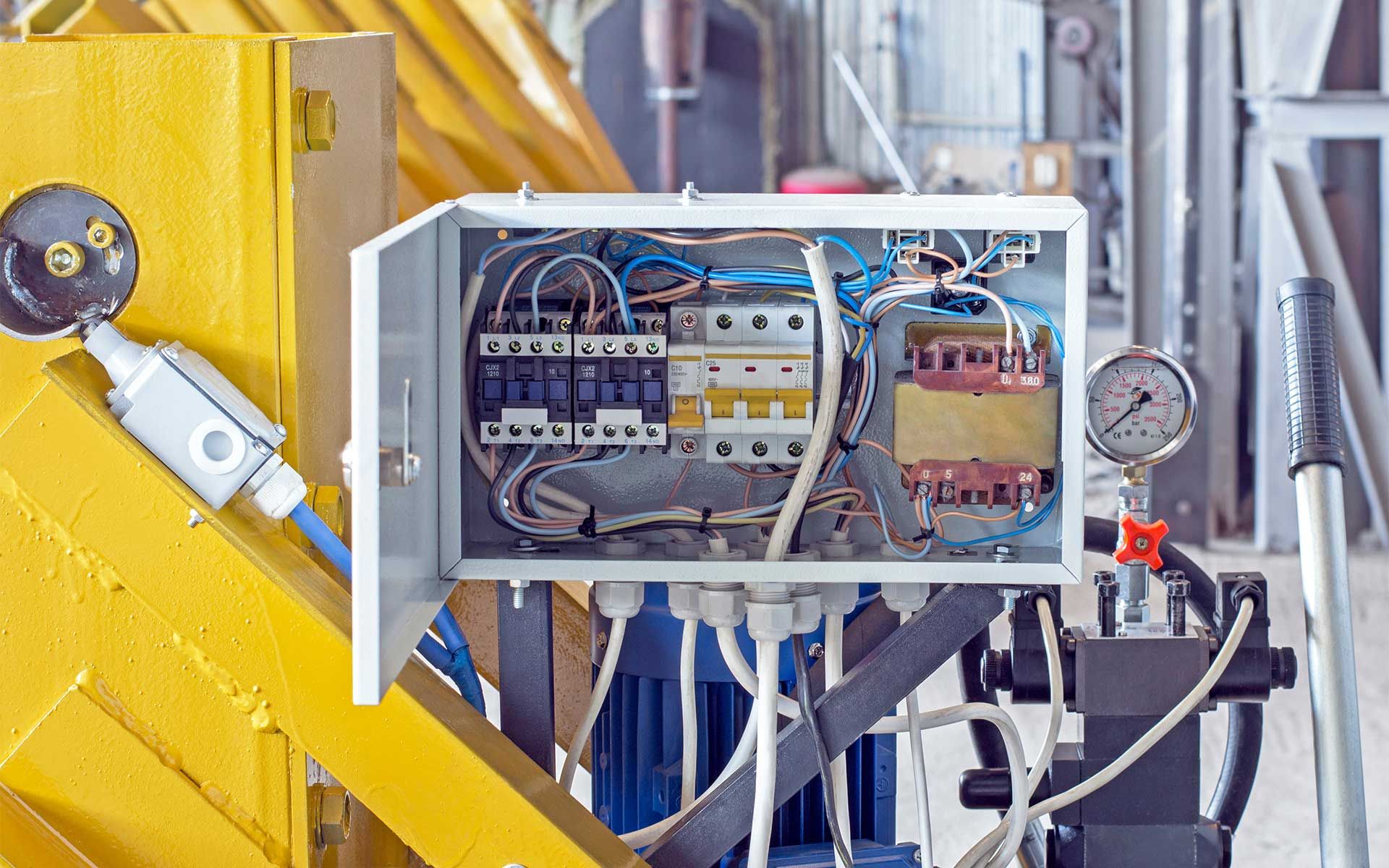

Factories and machines rely on limit switches a lot. Imagine a place with heavy machines running all day, making lots of noise and dust. There, the switches must watch carefully for any sign of an object moving into place or leaving its spot — without fail.

Even in these wild conditions, they send clear signals that help keep everything running smooth and safe.

Unaffected by exposure to water and dust

Honeywell's limit switches stand strong in wet and dusty conditions. These rugged devices offer top-notch protection with IP66/67 sealing. They keep working smoothly, no matter how tough the environment gets.

Built to last, they handle everything from splashes to dust storms without a hitch.

Workers rely on these switches every day across many industries. Farms use them on agriculture equipment that often gets dirty. Transportation companies trust them to operate efficiently, even during bad weather.

Honeywell makes sure their limit switches are ready for anything so businesses can keep running without worry.

Provide reliable, consistent operation for a range of applications

Honeywell limit switches stand up to the challenge in various settings. These robust devices control machinery, monitor conveyor systems, and help with building automation. Their tough design ensures they work well even in harsh conditions like dust and water exposure.

Different applications rely on these switches every day. They play a crucial part in ensuring emergency stop functions work right away. The switches also make it possible for assembly lines to run smoothly without hiccups.

Trust Honeywell to keep operations moving without fail, no matter the task at hand.

Enhanced Technology for Longevity and Dependability

In the quest for higher durability and reliability, Honeywell has honed its limit switches using cutting-edge solid-state technology. These advancements lead to a longer operational life and more consistent performance in demanding industrial settings.

Development focused on improved designs

Honeywell has pushed the boundaries with solid-state technology to craft better limit switches. These new designs boost their lifespan and make them more dependable than ever. Now, these switches perform even under harsh conditions without giving up.

Their upgraded models carry features for a broad range of industrial tasks. Thanks to Honeywell's commitment, users get consistent results from their heavy-duty machinery and general purpose conveyors.

The improved components ensure that machines work smoothly, with fewer interruptions or breakdowns.

Solid-state technology advancements

Solid-state technology has taken limit switches to the next level. Newer designs last longer and are more trustworthy thanks to this tech. They work really well in tough places where there's a lot of water or dust.

Engineers keep making them better, so they do their job without fail over and over again.

Pre-cabled options are now available for some solid-state switches, which makes setting them up easier. These advancements help machines talk to each other smoothly and safely, using logic-level controls like PLCs.

With Honeywell's improvements, industrial applications run smoother than ever before.

Components of Industrial Limit Switches

Delving into the anatomy of industrial limit switches illuminates their robustness and precision. At the heart of these devices are crucial components that ensure seamless interaction with various mechanical systems.

Operating head and actuator

Limit switches have a crucial part called the operating head and actuator. This piece senses objects as they come close or move away. It has different shapes to fit the job, like top plungers, side rotary with rollers, or wobble - coil springs.

These heads can take on tough tasks in factories and outside where it might be wet or dusty.

Honeywell designs these parts to meet strict standards for durability and performance. They work well in places with lots of movement, heavy machinery, and extreme temperatures. You can find them helping out in transportation equipment, controlling robotic arms, or making sure landing gear operates smoothly on airplanes.

Their reliable snap action keeps machines safe and efficient.

Switch body

The switch body is a vital part of industrial limit switches. It keeps the internal parts safe and in place. This component ensures that everything works well and lasts long, even in tough settings.

Honeywell designs switch bodies to be strong and reliable.

These bodies can handle being around water, dust, and other rough conditions without breaking down. Solid-state technology has made them even better over time. For certain jobs, Honeywell provides versions with cables already attached, making installation easier.

Contact block

Contact blocks are key parts of industrial limit switches. They handle the electrical connections that turn machines on or off. These blocks come in different forms, such as normally open or normally closed.

This means they can work with various types of equipment.

Honeywell designs contact blocks to fit compact housings and withstand tough conditions. They ensure long-lasting performance for devices like motors, dampers, and relays. Honeywell's contact blocks also match standards like UL/CSA/CE/CCC approvals.

This makes them safe and reliable for all kinds of industrial uses.

Honeywell's Offerings for Industrial Applications

Honeywell's array of limit switches caters to diverse industrial needs, ensuring that whichever application businesses rely on, there is a robust and precise switch solution ready to meet the demand.

Pre-cabled options for select applications

Some industrial tasks need quick and easy setup. Honeywell meets this need with pre-cabled limit switches. These switches come ready to connect, cutting down on installation time. They are perfect for jobs where wiring could be tough or when speed is key.

Customers find these pre-wired options handy for a smooth operation. With everything set up, workers can plug and play without fussing over complex wiring details. This helps get machines running faster and more reliably in tough industrial settings.

Conclusion

Honeywell limit switches are tough and trustworthy. They handle extreme conditions without a problem. With their solid-state technology, they work well for many industrial jobs. Honeywell makes choosing the right switch easy with pre-cabled options.

These switches help machines sense things accurately every time.

FAQs

What are Honeywell limit switches?

Honeywell limit switches are electromechanical devices that control machinery movement in industrial applications.

Can these switches work with programmable logic controllers (PLCs)?

Yes, Honeywell's general purpose limit switches can connect to PLCs for precise operations in various environments.

Are there different types of Honeywell limit switches?

Definitely! You'll find snap-action switches, micro switch products, and more options like side rotary with rod or top roller arm designs.

Is technical information available for these switches?

For sure! Each product has a data sheet and technical documentation to help you understand all the details about the switch, including conduit/connectivity options.

Do Honeywell limit switches have protection against tough conditions?

Yes! Some models come as environmentally sealed switches and may include features like metal housing and IP66 sealing to resist corrosive substances.

Where can I get updates about new offerings or special offers on Honeywell limit switches?

You can receive exclusive communications from Honeywell about product updates, new offerings, and special offers just by checking their inventory or signing up for notifications.