Countless industries rely on electrical systems to operate, from heavy machinery in industrial manufacturing to sensitive avionics equipment in the aerospace industry. With so much riding on electricity’s ability to power systems across sectors, safety measures are paramount to maintaining the overall stability of these critical systems.

Enter the current limiting fuse, an electrical protection device integral to the electrical system operation and personnel safety. Today’s blog post takes an in-depth look at the role of current limiting fuses in electrical systems' operational safety, the types available, their applications in modern electrical systems, and more.

- Introduction to Current-Limiting Fuses (Limiter Fuses)

- How Current-Limiting Fuses Enhance Safety

- Applications in Modern Systems

Introduction to Current-Limiting Fuses (Limiter Fuses)

Current limiting fuses, also commonly called limiter fuses, play a crucial role in electrical system protection and safety. Like most electrical system components, these limiter fuses are small and compact in size - yet integral to the overall function and safety of systems that rely on electrical currents to operate.

Definition and Functionality

Let’s begin with the basics, i.e., What is a current limiting fuse? A limiter fuse is a type of electrical protection device designed to quickly and effectively limit the flow of excessive current in an electrical circuit during a fault condition. How quickly? A current-limiting fuse is designed to open and clear a fault in less than 180 electrical degrees or within the first half electrical cycle (0.00833 seconds).

By offering this fast and precise protection during short circuits or other overcurrent situations, current limiting fuses help prevent damage to equipment, reduce the risk of fire and electrical hazards, and maintain the overall stability of the electrical system.

Therefore, modern electrical systems depend on current-limiting fuses to safeguard equipment and wiring from damage in overcurrent situations, ensure the safety of personnel, maintain operational continuity, and adhere to industry safety regulations. All of these functions make limiter fuses a cornerstone of effective electrical protection strategies.

Importance in Electrical Circuits

Virtually all electrical systems have electrical circuits, which provide a closed path through which electric current can flow. Essentially, electrical circuits consist of interconnected components such as power sources, conductors (wires), switches, resistors, capacitors, inductors, and loads (devices that consume electrical energy) - all forming this closed loop or path.

When abnormal conditions result in an excessive flow of electric current through this path, such as with short circuits or component failures, potentially hazardous situations, equipment damage, and disruptions in the electrical system can occur. However, a current limiting fuse can provide the needed protection for electrical circuits under these circumstances by quickly interrupting and limiting excessive current flow before it can damage equipment or personnel.

Other fuse types are fast acting and time delay slow blow fuses. These two categories encompass a variety of fuse designs and models tailored to different applications and voltage/current ratings.

Fast-acting

A fast-acting fuse responds quickly to overcurrent conditions, rapidly interrupting the circuit to prevent damage. These fuse types are known for their current limiting capabilities and high-speed fault clearance. So, for example, when the current in an electrical circuit exceeds a certain threshold, the fuse rapidly interrupts the circuit, reducing the amount of energy released and mitigating potential hazards.

These characteristics make fast-acting limiter fuses suitable for a variety of applications, from low-voltage systems to high-power distribution networks, to ensure the safety of the equipment, operating personnel, and the stability of the electrical system overall.

Time-delay

Time-delay fuses, on the other hand, have a characteristic delay before they blow, allowing them to tolerate temporary overcurrents without tripping. These current limiting fuse types are designed with a special element that gradually melts when subjected to sustained overcurrents, which prevents the fuse from blowing instantaneously during short-duration surges or inrush currents.

Time-delay fuses often have higher current ratings compared to their fast-acting counterparts. This is because they are meant to tolerate temporary overcurrents without tripping while providing effective protection against prolonged overloads and short circuits. These features make time delay current limiting fuses ideal for applications where devices experience initial high inrush currents, such as motors, transformers, capacitors, and fluorescent lighting circuits.

How Current-Limiting Fuses Enhance Safety

Current-limiting fuses are designed to respond rapidly to high fault currents, which are typically caused by conditions that allow a large amount of electric current to flow through a circuit. These conditions - including but not limited to short circuits, lightning strikes, ground faults, and equipment failures - create a low-resistance path that allows current to travel unrestricted, often resulting in potentially hazardous situations.

By quickly interrupting the flow of excessive current during a fault condition, these fuses prevent the fault from escalating, minimizing potential damage to equipment and wiring.

Overload Protection

Fuses play a critical role in protecting electrical systems and enhancing safety, particularly when it comes to overload protection. This protection is essential to prevent excessive currents that can damage equipment, cause fires, and pose hazards to personnel. Current limiting fuses, including both fast-acting and time-delay types, provide effective overload protection and enhance safety by interrupting the circuit and stopping the flow of current when it exceeds a certain threshold.

Short Circuit Protection

Short circuits pose numerous threats to electrical systems, including high fault currents, equipment damage, fire hazards, and electrical shock. However, current limiting fuses (fast-acting and time-delay) are designed to protect circuits from these dangers in short-circuit situations by quickly interrupting high fault currents - thereby limiting energy release and preventing damage.

These predictable tripping characteristics rapidly interrupt fault currents to protect sensitive equipment such as motors, transformers, and electronics from the damaging effects of short circuits, allowing for emergency shutdowns that prevent further damage or hazards from occurring.

Applications in Modern Systems

In modern electrical systems, current limiting fuses are vital to the safe operation of electrical systems in countless applications across industries worldwide. From data centers to aviation, operations within these industries depend on current limiting fuses to enhance electrical system safety and maintain operational reliability. Following are a few examples of how current-limiting fuse types protect the critical electrical applications that keep industries running.

- Industrial Manufacturing: Industries that involve heavy machinery, motors, and automation systems use current limiting fuses to protect equipment from overcurrent conditions, ensuring continuous production and minimizing downtime.

- Data Centers: Data centers rely on current limiting fuses to prevent overcurrents that could damage critical servers, networking equipment, and sensitive electronics, ensuring uninterrupted data processing.

- Automotive Manufacturing: The automotive industry uses current limiting fuses to safeguard assembly line machinery, robotic systems, and vehicle manufacturing processes from electrical faults.

- Use in isolating faults in battery operated systems.

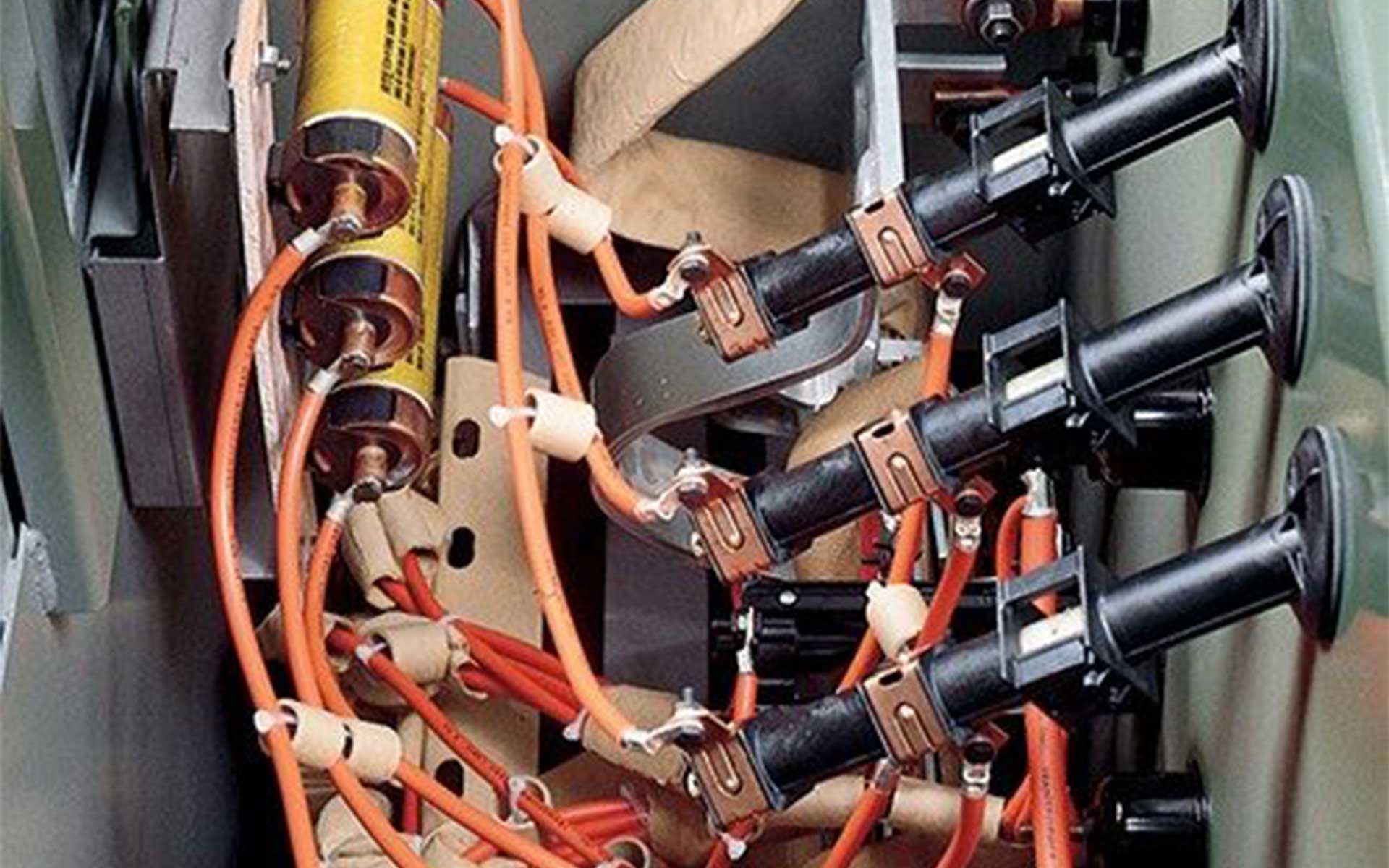

- Aerospace: Aerospace facilities use current limiting fuses to protect sensitive avionics, electrical systems, and ground support equipment from electrical faults.

Conclusion

All current limiting fuse types play a pivotal role in averting harm, ensuring safety, and upholding the uninterrupted operation of contemporary electrical systems. Their adherence to industry standards further underscores their significance as a fundamental element of robust electrical protection strategies. Given that electricity powers our world, the safeguards provided by current-limiting fuses are paramount for preserving the integrity of countless systems reliant on its power.

Eaton Bussmann series fuses play a significant role in industrial and commercial facilities by providing reliable, maximum protection to power systems. Their physical size or rejection features prevent replacing a fuse with one from another fuse class, thereby ensuring the correct replacement is selected, and the voltage and interrupting ratings remain the same. Peerless has been an authorized distributor for Bussmann products since the 1950's.